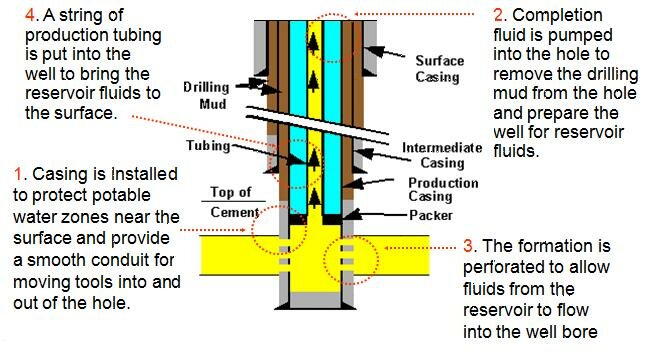

After a well has been drilled, it must be completed before oil and gas production can begin. The first step in this process is installing casing pipe in the well.

Oil and gas wells usually require four concentric strings of pipe: conductor pipe, surface casing, intermediate casing, and production casing. The production casing or oil string is the final casing for most wells. The production casing completely seals off the producing formation from water aquifers.

The production casing runs to the bottom of the hole or stops just above the production zone. Usually, the casing runs to the bottom of the hole. In this situation the casing and cement seal off the reservoir and prevent fluids from leaving. In this case the casing must be perforated to allow liquids to flow into the well. This is a perforated completion. Most wells are completed by using a perforated completion. Perforating is the process of piercing the casing wall and the cement behind it to provide openings through which formation fluids may enter the wellbore.

The blowout preventer (BOP) is a large valve at the top of a well that may be closed if the drilling crew loses control of formation fluids. By closing this valve (usually operated remotely via hydraulic actuators), the drilling crew usually regains control of the reservoir, and procedures can then be initiated to increase the mud density until it is possible to open the BOP and retain pressure control of the formation. BOPs come in a variety of styles, sizes and pressure ratings. Some can effectively close over an open wellbore, some are designed to seal around tubular components in the well (drillpipe, casing or tubing) and others are fitted with hardened steel shearing surfaces that can actually cut through drillpipe.

(Source: Schlumberger Oilfield Glossary)

On Wednesday May 12, 2010, a House energy panel found that the blowout preventer that failed to stop a the oil spill had a dead battery in its control pod, leaks in its hydraulic system, a "useless" test version of a key component and a cutting tool that wasn't sharp enough to shear through steel joints in the well pipe and stop the flow. The well must now be filled with cement to permanently close well.

(Source: "Blowout preventer was in bad repair," Dallas Morning News, May 13, 2010, p. 1A.)

Click on picture to enlarge

(Source: "Well may be filled with cement this week," Dallas Morning News, August 1, 2010)

BP announced on August 4, 2010 that more than 96,000 gallons of mud forced down the well in the "static kill" operation had finally plugged the well. However, concerns linger as to ongoing cleanup efforts and the long-term affect of the spill on the ecosystem.

(Source: "Well is plugged, but doubts about dissipating oil haven't subsided," Dallas Morning News, August 5, 2010)

BP finished pumping fresh cement into the wellbore on August 5, 2010. The Coast Guard said that this was the end and retired Coast Guard Admiral Thad Allen said "it will virtually assure us that there will be no chance of oil leaking into the environment." However, on a disturbing note, BP has refused to say whether it will use the two relief wells to plug the well for good. The company has said that it might not need to use the relief wells to plug the leak and might instead use one of them as a production well. [Given BP's record this should start sounding warning bells-Editorial Comment]

(Source: BP finishes bolstering mud plug with cement, Dallas Morning News, August 6, 2010)

No comments:

Post a Comment